WTViewerE Application Software

WTViewerE software enables PC connectivity for Yokogawa power analyzers such as the WT5000, WT3000E/ WT3000, WT1800E/ WT1800 , WT500 and WT300E/WT300 through Ethernet, USB, GPIB or RS232. With multichannel measurements, multi-unit connectivity and multilingual support, the WTViewerE allows users to easily control, monitor, collect, analyze, and save remote measurements from up to any 4 power analyzers simultaneously.

Furthermore, this software supports the waveform data streaming function using the WT5000.

Features

| Test Application: ●Automotive Power Train ●Wind Power Inverter ●Motors/Drives/Inverters ●Home/Office Appliances ●Solar Power Inverter |

|

|

|

WTViewerE Power Measurement Software  |

||||||||

| *Simultaneous connections of up to 4 units | Measurement , Remote Control Multi-Unit Synchronization Visualization and Analysis |

|||||||||||

|

Real-time Control |

Measurement Screen (online) |

|

Multi-unit Connectivity With customizable split screen display of readings in numeric, bar, trend or vector formats, the WTViewerE simplifies the acquisition, storage and analysis of multichannel measurements from up to 4 power analyzers simultaneously. |

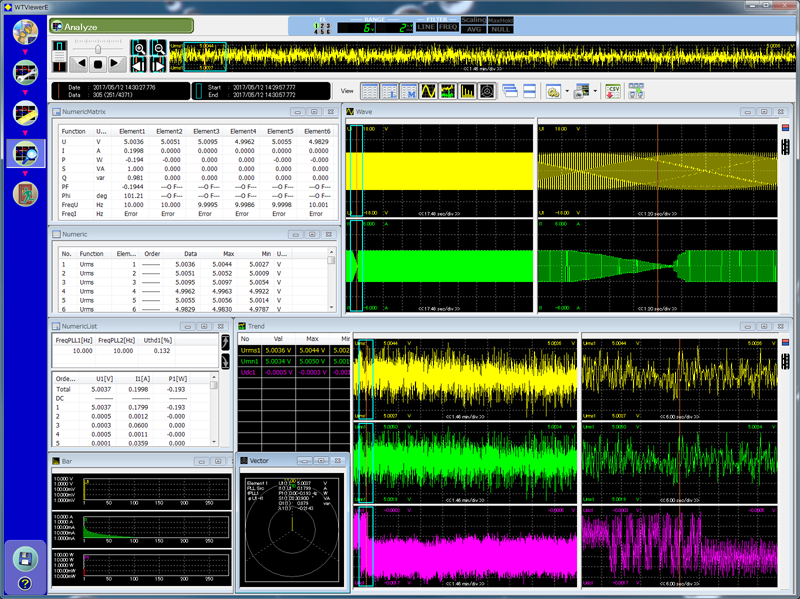

Analysis Screen (offline) |

|

High Speed Waveform Capture and Synchronized Measurement of Waveform and Power Parameters |

|

|

The WTViewerE and WT5000 /DS option (data streaming) enable acquisition of high-speed waveform data at up to 2 million samples per second (2MS/s) and easy synchronized measurement of waveform and power parameters. Acquired data can be saved or output to a CSV file. The figure on the left shows a waveform acquired by data streaming over a duration of 1 second and the details of the waveform (magnified by 100 times). Data Streaming Description Since the streamed waveforms are synchronized with power parameters, analysis of both makes it possible to understand changes in the noise on the waveform or in the control state. Through changes in the waveform, more detailed analysis is possible, such as how a change in the noise or control state affect the power value and each parameter. |

|

|

Ideal for multichannel power measurements |

|

|

The WTViewerE allows users to :

|

|

| WT Series Models | WT5000 (firmware 3.01 or later) WT3001E/WT3002E/WT3003E/WT3004E WT3000 (760301/760302/760303/760304) (firmware 6.11 or later) WT1801E/WT1802E/WT1803E/WT1804E/WT1805E/WT1806E WT1801/WT1802/WT1803/WT1804/WT1805/WT1806 (firmware 2.31 or later) WT500 (760201/760202/760203) (firmware 1.21 or later) WT310E/WT310EH/WT332E/WT333E WT310/WT310HC/WT332/WT333 |

| The WTViewerE allows simultaneous connection of different WT series models. Example: WT3000E-WT1800E, etc. It also allows simultaneous connection of the same models with different input element types/numbers or different options. |

|

| Display screen | Measuring Item: Normal, harmonics, integration |

| Functions | Display Screens: numeric, waveform*1, trend, harmonic list*2, Bar Graph*2 and vector*2*3 *1 Harmonic measurement option must be installed in the WT300 or WT300E. *2 Harmonic measurement option must be installed in the WT. *3 A vector window cannot be displayed on the WT300 or WT300E. |

| Data Acquisition Interval:50 ms at max. speed. - The data storage period can be any custom settings (more than 20 seconds) and the data update rate of the product. - Depends on your PC's processing speed, the communication interface is use, and the number of data points that the software is collecting from the WT. - When the data acquisition interval is 500 msec or less, dropout of waveform data will occur on regular basis. |

|

| Data conversion formats |

Numeric and Waveform data: CSV format (.csv) |

| Languages Supported | English, Japanese, Simplified Chinese, German, Italian, Korean, Russian, Spanish, French, Hungarian |

System Requirement

| PC | CPU | Equivalent to Intel Core i5-2430M or better |

| Memory | 4 GB or more recommended | |

| Storage*4 | 1TB free space or more | |

| OS | English version of Windows 8.1, or Windows 10 | |

| Communication Board | GP-IB | NI (National Instruments) |

| PCI-GPIB or PCI-GPIB+ PCIe-GPIB or PCIe-GPIB+ On Windows 8.1: Use driver NI-488.2 Ver.3.1.0 or later. On Windows 10: Use driver NI-488.2 Ver.15.5.0 or later. |

||

| GPIB-USB-HS On Windows 8.1: Use driver NI-488.2 Ver.3.1.0 or later. On Windows 10: Use driver NI-488.2 Ver.15.5.0 or later. |

||

| GPIB-USB-HS+ On Windows 8.1. On Windows 10: Use driver NI-488.2 Ver.15.5.0 or later. |

||

| RS-232 | An available PC COM port | |

| Ethernet | An Ethernet port that supports 10BASE-T, 100BASE-TX, or 1000BASE-T | |

| USB | A USB port that supports USB Revision 1.1 or higher | |

| Display, Printer, and Mouse | Screen Resolution | 1366×768 pixels or higher |

| Disk Drive | A drive that can read CD-Rs | |

| Operating System | Must be compaible with the operating systems listed above. | |

*4 Storage Capacity

This software saves all displayed measured data.

Depending on the combination of setup items that affect the data size, the data may exceed 1 TB.

Reference

Reference: Measurement data size

| Measurement time | Normal Measurement Data | Data Streaming Waveform Data |

| 10 minutes | Approx. 15 MB | Approx. 5 GB |

| 1 hour Approx. | 88 MB | Approx. 288 GB |

| 1 day | Approx. 2.1 GB | Approx. 7 TB |

| 1 month | Approx. 63 GB | --- |

| Measurement conditions: | Normal Measurement Data | Data Streaming Waveform Data |

| • Model | WT1806/G6/DT/MTR | WT5000/DS |

| • Number of connected devices | 1 | 1 |

| • Update interval | 1 s | 1 s |

| • Number of waveform display functions | 2 | 2 |

| • Number of numeric list display functions | 3 | 3 |

| • Number of bar display functions | 1 | 1 |

| • Data streaming waveform | None | Present Sample rate: 1 MS/s |

As the file size increases, the processing load for analyzing measured data may become extremely heavy.

The situation may improve by changing the storage medium.

(Slower) HDD < SSD < M.2.SSD (Faster)

WT5000 Data Streaming (/DS)

Conditions of Use

- This software version: 1.51 or later

- WT5000 firmware version: 2.01 or later

- Online connection: USB3 or later or Gigabit Ethernet or later

Sample Rate during Data Streaming Waveform Acquisition and Maximum Number of Waveforms That Can Be Acquired

| Maximum Number of Waveforms | ||

| Sample Rate [S/s] | USB3 | Gigabit Ethernet |

| 10 k | 22 | 22 |

| 20 k | 22 | 22 |

| 50 k | 22 | 22 |

| 100 k | 22 | 22 |

| 200 k | 22 | 22 |

| 500 k | 14 | 6 |

| 1 M | 6 | 4 |

| 2 M | 2 | 2 |

- Use the data streaming waveform acquisition feature by connecting a single unit.

- The update interval is fixed at 1 second during data streaming waveform acquisition.

- The on/off state of the data streaming waveform function is synchronized to that of the waveform display.

- Under Data Size Information, the required free storage size is displayed depending on the data acquisition time (hour/minute/second), which is based on the sample rate and number of waveform channels.

- Prepare enough free storage according to the acquisition time.

Brochures

Instruction Manuals

- Read before Installing the Software (761941 WTViewerE) (126 KB)

- Application Software WTViewerE User's Manual (7.9 MB)

Software

How-tos

- Measuring Individual Phase Power on Three Phase Systems

- Standard Delta computation function

- Available on Yokogawa WT5000 Precision Power Analyzer